IT TOOK the work of many inventors to bring about the changes of the Industrial Revolution, but the man recognized as the greatest inventor of the age was James Watt, whose name is linked with the steam engine. Actually the steam engine was invented and used in coal mines long before Watt was born. What he invented was a greatly improved type of steam engine which was practical enough to make steam power available to factories for the first time. As a result of his invention, many large power-driven factories soon sprang into being, some of them employing hundreds of workers. Such factories could produce cloth so cheaply that it was almost impossible for people to make a living by spinning and weaving by hand in their homes.

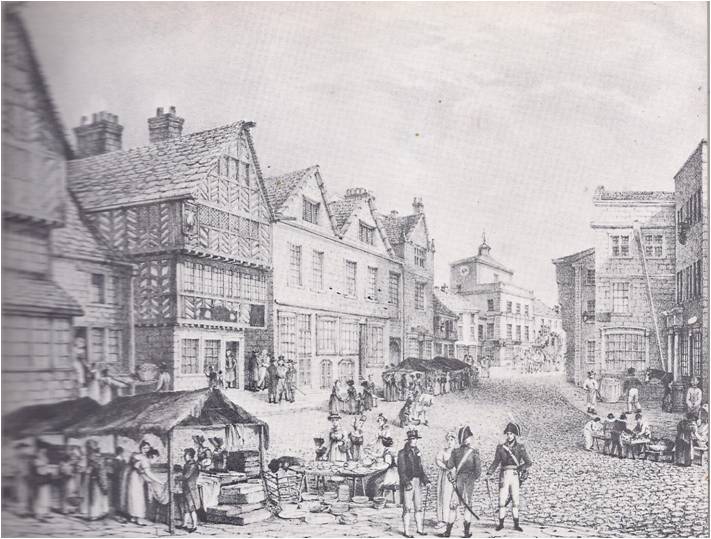

All the important changes of the Industrial Revolution took place during the span of James Watt’s lifetime. In 1736, the year of his birth in Scotland, spinning and weaving was still being done at home. Peasants not only made their own clothes, but also wove cloth to sell in the market place. Almost every country cottage had its spinning wheel and weaving loom. Wooden tubs were used to wash the raw wool and to color the finished cloth with dye.

On the land surrounding the cottage, each weaver usually had a garden and kept a cow or two, some poultry and a horse. It was natural that he should feel close to the land, for his people had been farmers for many centuries. During the planting seasons and the busy times of harvest, he and his family let the spinning wheels and the loom stand idle while they worked in the fields. During the growing seasons and the long winter months, they devoted full time to spinning and weaving.

It took five or six spinners to make enough thread to keep one weaver busy at his loom. If a weaver did not have that many spinners within his own home, he went from house to house in search of spinners whom he could hire to spin some of his wool into thread. Sometimes, in a good year, he had enough money to buy a large amount of raw wool. Then he would hire many spinners and several weavers to help him make his cloth. In this way he became a manufacturer, with a number of employees under him, each working in his own home.

TRADERS AND EMPLOYERS

The weaver would sell his cloth in one of the large markets close to his village. In Halifax, one of the large cloth markets, weavers brought their cloth to market on Saturdays. So many weavers came that many could not get into the large market hall. The late-comers displayed the cloth on the streets and in the inn. By evening the cloth merchants had usually bought up every piece of cloth in sight and the weavers headed for home on horseback or in small carts.

In time, the weavers produced more cloth than they could sell at the local markets. Traders bought up the extra cloth at bargain prices and offered it for sale in markets some distance away. Some traders hired workmen to dye the cloth bright colors, or to finish the cloth in some special fashion. In this way traders became employers. They found that they could make larger profits by buying raw wool and hiring spinners and weavers to make it into cloth. It was easy to hire people at low wages, for the towns were crowded with peasants looking for work. Here and there an employer gathered ten or twelve weavers together and put them to work in a building he provided for them.

These small manufacturers were quick to try new inventions that promised to cut down costs and increase profits, such as James Hargreave’s spinning jenny. With the new jenny one woman could spin six or seven threads at the same time, thus doing the work normally done by six or seven women using spinning wheels.

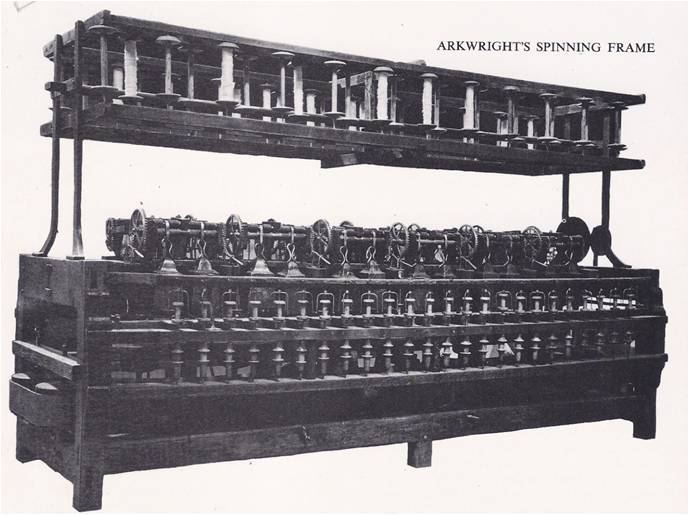

In 1769, Richard Arkwright was granted a patent on the water-frame. It could spin many threads at the same time, threads much stronger than those made by the spinning jennys. But the water-frame could not be operated by hand. Arkwright used water power to turn his spinning machines. It was not long before a weaver named Samuel Crompton invented a still better spinning machine, which combined the best features of the spinning jenny and the water-frame. This new machine became known as the mule. It produced a thread that was fine and strong and could be used for weaving several kinds of cloth, including fine muslins.

THE COTTON GIN

Crompton’s new spinning machines produced thread much faster than the hand-loom weavers could weave it into cloth. The weavers were given higher pay to encourage them to work faster. They did, but there were not enough of them to satisfy the demand for the popular new muslins. This was “the golden age of the weavers,” when they earned more than they ever had before. They dressed in fancy style, carried canes and had paper money sticking out of their hatbands. They looked down on workmen of other trades and would not permit such workers to enter the taverns where weavers gathered, but the golden age did not last long. Thousands of men and women learned how to weave and joined the ranks of the weavers. Worst of all for the weavers, Edmund Cartwright invented a power loom in 1784, but it needed many improvements and was not widely used for a number of years.

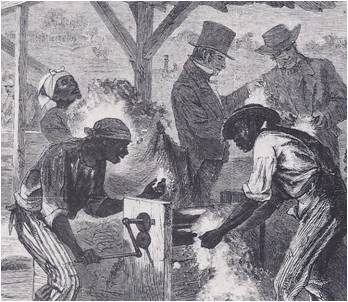

The new methods of spinning and weaving greatly increased the demand for raw cotton and the American cotton plantations had difficulty keeping up with the demand. The reason was that the seed had to be hand-picked out of the cotton and this was very slow work. A Connecticut Yankee named Eli Whitney heard about the problem when he went south to serve as a tutor on a plantation in Georgia. Soon he had invented the cotton gin, a machine which separated the cotton from its seed much faster than it could be done by men. The plantation owners began to plant more cotton and to buy more slaves to work in the fields.

By 1820, England was importing five times as much cotton as she had been thirty years earlier and the making of cotton cloth had become her most important industry. It was James Watt’s steam engine that made such rapid growth possible.

According to legend, James Watt first became interested in the power of steam when he was a boy, watching the lid dance on a bubbling kettle.

As he grew up in Greenock, Scotland, young James spent many hours watching his father repair instruments of navigation for sailing ships. James was good with tools and enjoyed making small objects for model sailing ships. By the time Watt was twenty, he had decided to become a maker of scientific instruments. He had learned a great deal about such instruments from his father, but he wanted to work and study under one of the master instrument makers in London. Since there were no stagecoaches from Scotland to London, Watt went on horseback, a twelve-day journey.

France and England were at war at the time and young Watt found London so dangerous a place to live that he remained indoors as much as possible. Press gangs roved the streets, capturing young men for service in the British navy. Sometimes as many as a thousand men were taken in the streets in a single night. There were also kidnapping bands which would seize anyone who could serve as a laborer on British plantations in the West Indies.

WOOD, COAL AND IRON

After a year with a London instrument maker, Watt felt he had learned enough to go into business for himself. He returned to Scotland and opened a shop on the grounds of the University of Glasgow. From friendly teachers and students Watt learned a great deal about the qualities of heat and steam. He later wrote: “My attention was first directed in the year 1759, to the subject of steam-engines, by the late Dr. Robison, then a student in the University of Glasgow and nearly my own age. He at the time threw out an idea of applying the power of steam engines to the moving of carriage wheels and to other purposes; but the scheme was not matured and was soon abandoned on his going abroad.”

Watt could not abandon this idea. His thoughts kept coming back to steam power and he began reading about the early development of steam engines. He found that the first steam engine of any real practical importance was built by Thomas Newcomen about 1702. Oddly enough, there was much interest in steam engines at that time because of a serious shortage of wood. England’s forests were being cut down to make charcoal for the smelting of iron ore.

The fuel problem went at least as far back as 1548. In that year it was reported that the Sussex ironworks had destroyed so many of the forests in southern England that fishermen could hardly find enough fuel “to dry their clothes or warm their bodies when they came in from the sea.” The iron industry had continued to grow, using up many of Englands large forests. By 1700 the wood shortage had become so serious that the British were afraid there would soon not be enough timber left for the building of ships for the royal navy.

Many people believed that coal could be substituted for wood in the smelting of iron ore. Coal was already being used by a number of small industries. In London it was commonly used in winter for heating houses. There were shallow coal mines in many parts of England and wherever there was coal mines there were usually iron mines not far away. Shallow mines could not supply the large amounts of coal needed by the iron industry. There was plenty of coal underground which could be reached by digging deep mines; the trouble was that deep mines usually filled with water.

Newcomen finally invented a steam engine that could be used to pump water out of the deep coal mines. The result was that large amounts of coal became available to the iron industry for the first time. By heating the coal in ovens, it was possible to turn it into a higher type of fuel known as coke, which was almost pure carbon.

Coke could be used in blast furnaces as a substitute for charcoal in the smelting of iron ore and this discovery made it possible to greatly increase the production of iron. In time iron came to be substituted for stone and wood in bridge building and other types of construction. It was also used in building ships. When the iron industry discovered ways of turning iron into steel, it became possible to make better machinery and tools than ever before.

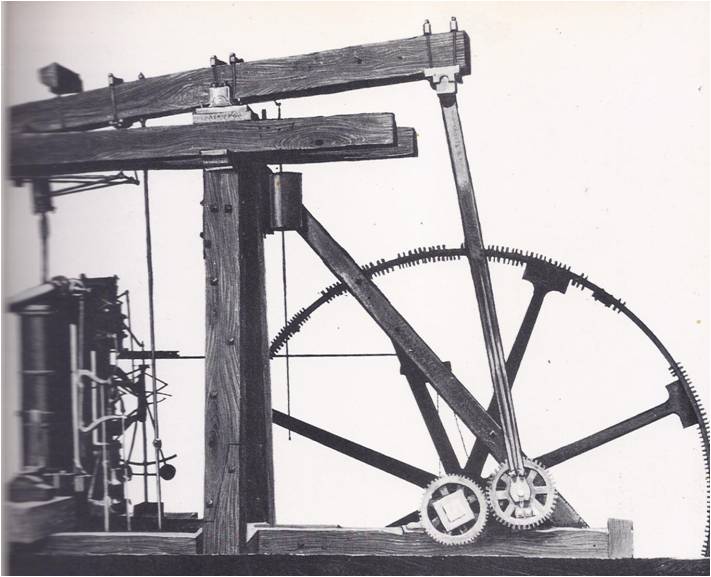

James Watt saw the Newcomen steam engine for the first time when he was asked to repair a model of it owned by the University of Glasgow. He was amazed to find that the engine wasted about three quarters of its energy. Much of the lost energy was wasted in heating and then cooling the cylinder with each stroke of the piston. On the upward stroke, the cylinder had to be heated while it filled with steam. Then it had to be cooled suddenly with a spray of cold water to condense the steam and create a vacuum so that the piston could come down again on the return stroke. Watt realized that the engine which wasted so much energy was of no practical value except in coal mines where fuel could he had in unlimited supply without cost.

“I can think of nothing but this machine,” he wrote to a friend in the spring of 1765. The engine would be greatly improved if he could cut down the loss of energy. But how?

The answer came suddenly one Sunday afternoon as he walked on the Green of Glasgow. What the engine needed was two separate steam chambers — a piston cylinder, which could be kept hot at all times and a cooling chamber where steam from the cylinder could be sprayed with cold water and condensed. A condensing chamber would do away with the costly heating and cooling of the cylinder with each stroke of the piston.

After a year of experimenting, Watt was deeply in debt. To support his wife and two children, he became a surveyor and he had very little time for the steam engine until John Roebuck, a businessman, took an interest in it. Roebuck became Watt’s partner, paying a thousand pounds for a share of the patent which Watt took out in 1769. Roebuck was also to pay the costs of all future experiments. His own business soon failed and his interest in the steam engine was purchased by Matthew Boulton, a wealthy manufacturer in Birmingham.

Once Boulton became his partner, Watt never lacked for money. He had the advice and help of the great ironmaster, John Wilkinson, who had just invented a way of boring holes in cannon that were considerably more accurate than any that had been done before. Watt adapted the invention to bare cylinders for his steam engines that were almost perfect.

Watt invented something he called a governor to keep the steam engine from running too fast or too slow. He also invented a double-action engine in which the piston was driven back and forth by steam pressure applied against it, first from one side and then from the other.

His engine used only about one-fourth as much fuel as the Newcomen engine and was soon in great demand by the iron industry. This demand increased after Watt invented a way of turning wheels with his engine. Then it could be used to work the blowers of large blast furnaces, the rollers in the iron mills and the big hammers that beat the red-hot bar iron into shape. Watt’s engine was used also in flour mills, in malt mills and in West Indian sugar mills.

In the cloth-making industry, Watt’s engine led to the rapid development of the factory system, bringing spinners and weavers from their homes into the factories. Large factories were now practical. They did not need to be located near coal mines, but could be built close to important trading centres where coal and raw materials were available and finished cloth could be sold.

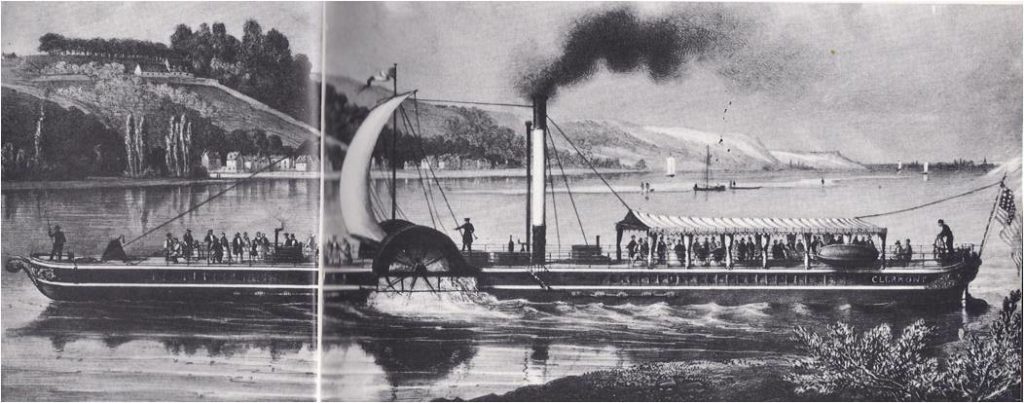

The rapid growth of industry greatly increased the need for transportation. Coal and iron had to be hauled to the factories and finished products had to be sent to markets in many parts of the world. Up to the time of the Industrial Revolution, heavy transportation in England had been pretty much limited to waterways and coastal routes. To fill the needs of mines and factories in all parts of the country, a whole network of roads had to be built. Many canals were dug and harbours and rivers were deepened. The first workable steamboat was developed by Robert Fulton in America, who used one of Watt’s steam engines for his trial run up the Hudson River. The importance of steam was not fully realized until George Stephenson developed a practical steam locomotive, which he demonstrated in England in 1829.